The next generation in portal bracing is here!

A strong but lightweight timber bracing solution, the PLX Portal revolutionises building construction. A smart and sustainable alternative to heavy, hard-to-install and emission-intensive steel portals, the PLX Portal is proudly designed and manufactured in New Zealand by Prolam.

Innovative design

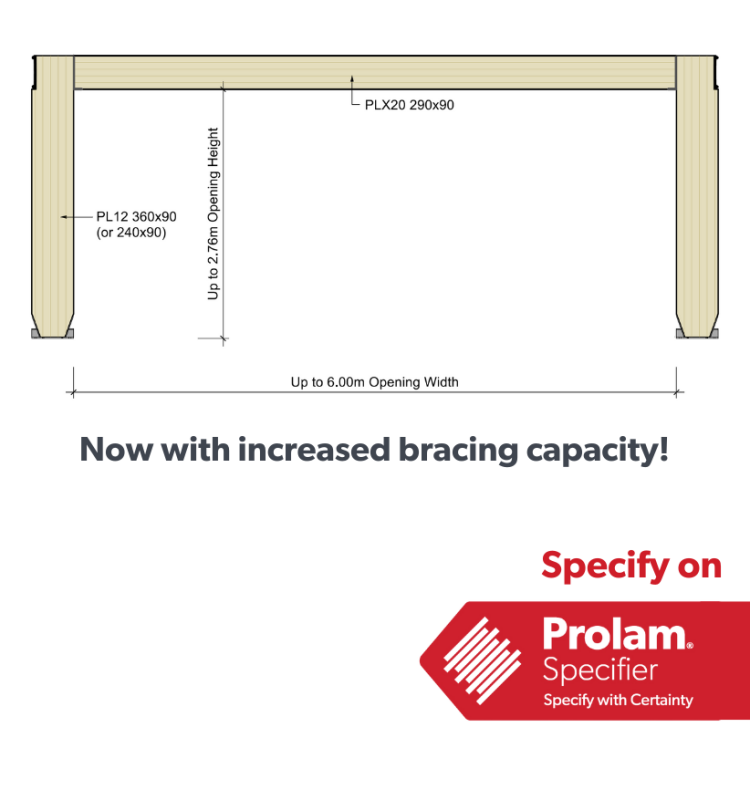

The PLX Portal is constructed from three glulam timber elements, including Prolam’s trademarked PLX20 Beam – precision engineered from quality radiata pine reinforced with steel for increased load bearing capacity. The reinforced beam offers excellent spanning capability to deliver optimal design flexibility for architectural features ranging from large internal openings to garage and window bracing portals or anywhere you need bracing but only have a narrow wall space.

Unmatched Installation Ease

The beauty of the PLX Portal lies in its lightweight construction and the simplicity of its onsite assembly and installation. The timber lintel and legs can be cut to length onsite to suit your project, assembled using standard tools, and installed and fixed without the need for extra labour, specialised skills or equipment such as cranes.

The new foot bracket design increases bracing capacity and provides a robust fixing solution for insulated foundations. The new top-down fixing ability enables a quicker and easier installation, speeding up the construction process.

A cut above

• Up to 40% lighter than steel portals

• High strength and durability

• Awesome spanning capability

• Simple on-site assembly using standard tools

• Fast installation – no extra equipment or staff

• FSC certified timber options available

• Easy to specify with PS1 certificate

• Highest timber bracing solution available

• Better insulation values than steel

• Cut to length to suit

• Made in New Zealand

Applications

• Large internal openings

• Garage portals

• Window portals

Now on the Prolam Specifier

Click Here to access our Design Service

Learn about our latest updates to the PLX Portal

Watch our Testing Videos

Contact Us for more information