Is your outdoor space in need of an upgrade?

Building pergolas using Prolam is made easy with straightness of product, premium quality & span tables for design.

A cut above

• PL8 & PL12 Structural grades readily available

• Premium quality and dimensional stability (no twisting or warping)

• H3.2 & H5 Treatment for exterior use

• Available in a wide range of sizes and lengths

• Renewable and Sustainable timber resource

• Codemarked Certified H5 Posts

• Quick and Easy design and installation

• Aesthetically Pleasing

Easy 5-step process to specify

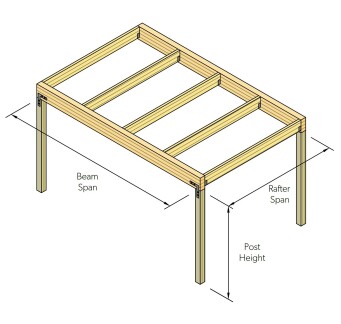

Designing and building pergolas using Prolam posts and beams is easy following our five-step process.

Step 1:

Determine the pergola size: length, width, and height.

Step 2:

Use Table 1 or 2 to select the correct sized outer beams.

Step 3:

Use Table 3 or 4 for rafter size based on the rafter and spacing.

Step 4:

Use Table 5 to work out the number and size of posts required..

Step 5:

Choose your Fixing options or enquire at your preferred merchant store.

Need help with your Pergola design?

Our sales team and in-house structural engineers are on-hand to support you to find the right solution for your project.

Fill in our Design form here and we'll be in touch!