A powerful bracing solution for open-plan designs

The Prolam PLX Column is a breakthrough in structural timber design. Developed in collaboration with architects, engineers and builders it overcomes a key challenge in modern construction: achieving bracing requirements without sacrificing space or layout.

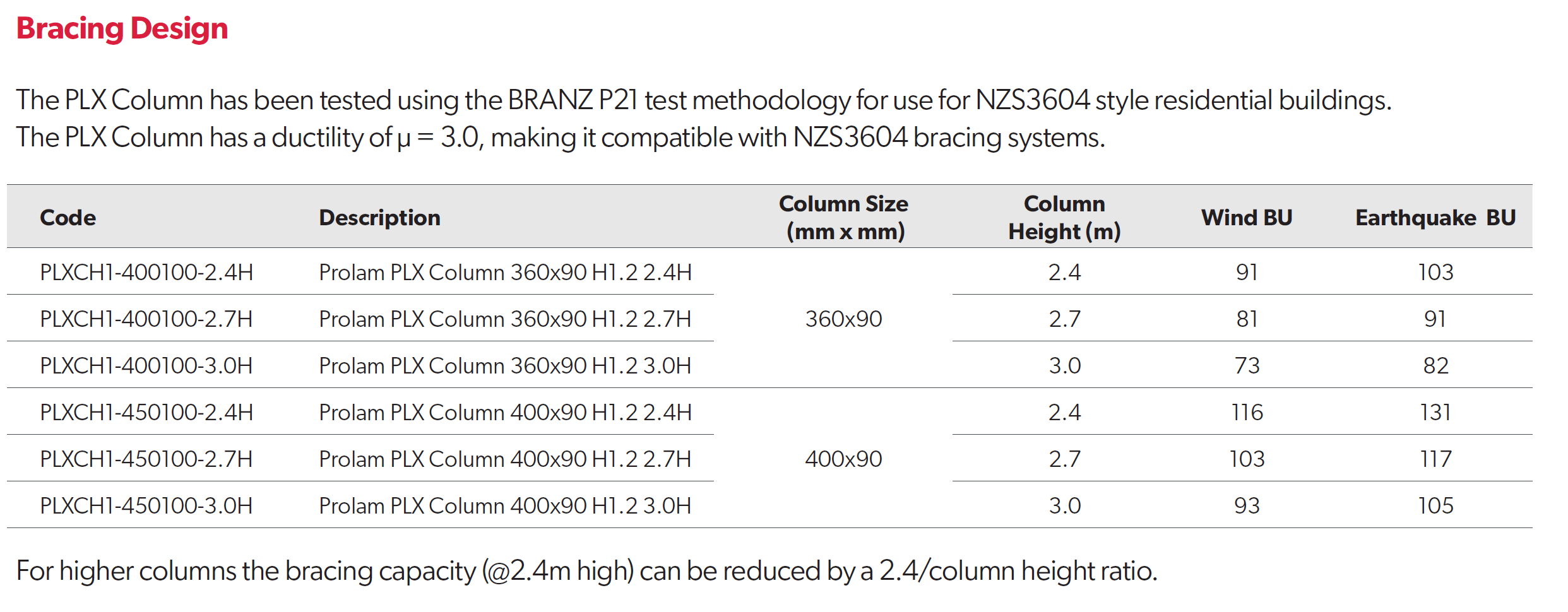

Delivering up to 120 bracing units in a single glulam member, the PLX Column is a space-saving, space-making solution for today’s homes. Available in 400mm x 90mm or 360mm x 90mm sizes, its compact footprint and high bracing capacity in minimal wall lengths allows you to create wider openings, cleaner lines and more light-filled, liveable interiors.

Cutting complexity on site

A simple fix and go solution, the PLX Column is delivered as a build-ready kitset including the prefabricated column and foundation connection.

Confident compliance

The product of extensive R&D and put through its paces at our testing facility, ProLab, the PLX Column meets and exceeds New Zealand building code requirements.

Tested in accordance with the BRANZ P21 (2010) bracing test and evaluation procedure, and third-party verified, the PLX Column provides bracing units to resist wind and earthquake loads.

Discover a smarter way to brace today.

Applications

The PLX Column has a wide range of applications for single storey dwellings and the ground floor of multi-storey buildings such as narrow townhouses and terrace houses where space is at a premium. It is ideal for:

• Open plan living areas.

• Kitchens.

• Entryways.

• Wing walls.

• Large openings.

Or anywhere you need bracing and have or want minimal wall lengths.

A cut above

• Premium glulam structural timber column

• Exceptional bracing capacity in minimal wall lengths

• Angled anchors for edges of insulated foundations

• Delivered as a prefabricated kitset ready to install

• Cut to length on site for an exact fit

• Connects easily to other timber members (no packing needed)

• Lightweight and easy to install

• Simple to specify with a PS1 Producer Statement

• A sustainable choice – made from NZ plantation grown pine

• NZ-made innovation

• Available nationwide

Contact Us for more information